History of KOBAYASHI

Founding

Everything started here

1954

1954

Nippon Musical Instruments Manufacturing Co., Ltd. (current Yamaha Corporation)

Received an order for processing of cam levers and camshafts for motorcycle YA-1 type brakes.

Taking this opportunity, GSK Kobayashi Iron Works started processing motorcycle parts.

1956

Universal precision gear cutter"MICRON"

Universal precision gear cutter"MICRON"

At that time, Kowa Manufacturing was a pioneer in introducing "MICRON" gear cutters in the Hamamatsu area.

1958

The Kobayashi Iron Works Nakajima Factory was producing musical instrument parts,

but it began remodeling the old lathe and starting broaching.

At that time, companies with broaching technology in the Hamamatsu area were rare, and they were busy with many orders.

In addition, Combined with Kowa Manufacturing's gear cutting, the ability to perform both gear cutting and broaching became a strength, and it became a valuable resource for customers.

In the second half of the year, a new broaching machine was purchased to improve productivity.

At that time, companies with broaching technology in the Hamamatsu area were rare, and they were busy with many orders.

In addition, Combined with Kowa Manufacturing's gear cutting, the ability to perform both gear cutting and broaching became a strength, and it became a valuable resource for customers.

In the second half of the year, a new broaching machine was purchased to improve productivity.

Company formation

a new start

1959

1959

Fully-operated Yamaha Motor Co., Ltd.

Production process (Hamana factory)

Production process (Hamana factory)

Kowa Manufacturing was renamed and Limited company Kobayashi Seiki Manufactory was established with a capital of 200.000 yen.

Acquired the cooperation factory from Yamaha Motor Co., Ltd.

1960

Purchased factory site in Ryuzenji, Hamamatsu City.

In September of this year, the capital of Kobayashi Seiki Manufactory was increased to 1 million yen.

In September of this year, the capital of Kobayashi Seiki Manufactory was increased to 1 million yen.

1961

Constructed a new factory on the factory site in Ryuzenji.

The Kobayashi Seiki Manufactory first moved, followed by the Kobayashi Manufacturing Co.,Ltd..

The Kobayashi Seiki Manufactory first moved, followed by the Kobayashi Manufacturing Co.,Ltd..

1964

The organ key mounting bracket, which had previously been made of steel,

was changed to aluminum.

In addition, production of center rails for pianos began in this year.

In addition, production of center rails for pianos began in this year.

Business expansion

KOBAYASHI's new challenge

1965

1965

Kobayashi Seiki Manufactory Teramiwaki Minami Factory completed in Terawaki Town

As a result, organ leg processing, which took about 20 minutes per machine, can now be done in 2 minutes. This greatly contributed to the increase in the production of electric organs in Nippon Musical Instrument Manufacturing Co., Ltd.

1966

A rolling machine was introduced at Kobayashi Seiki Manufactory.

The work that took 40 seconds to 2 minutes with a gear cutter was completed in just 2 seconds.

In September, the manufacturing departments of Kobayashi Seiki Manufactory and

Kobayashi Manufacturing Co. were merged to establish Kobayashi Industrial Co.,Ltd.

with a capital of 8 million yen.

The work that took 40 seconds to 2 minutes with a gear cutter was completed in just 2 seconds.

1968

Yamaha Motor Co. launches Snowmobile.

We processed column skis, which are the connecting part between the ski and the handle.

We processed column skis, which are the connecting part between the ski and the handle.

1970

A motorcycle assembly plant is completed at Yamaha Motor Co. Iwata factory.

From this time, the company's production of motorcycles increased rapidly.Our company, a partner factory, was also forced to make capital investments as soon as possible.

From this time, the company's production of motorcycles increased rapidly.Our company, a partner factory, was also forced to make capital investments as soon as possible.

1971

Manufactured hot water boiler parts and delivered them to

Nippon Musical Instrument Manufacturing Co., Ltd.

The company has also begun diversifying with the launch of a bathroom vanity along with a

hot water boiler this year.

On the other hand, Yamaha Motor Co. was also steadily set up for further production expansion, with the completion of the Yamaha Parts Center in February and the operation of the Nakase Factory in December.

On the other hand, Yamaha Motor Co. was also steadily set up for further production expansion, with the completion of the Yamaha Parts Center in February and the operation of the Nakase Factory in December.

1975

The production of furniture that Nippon Musical Instrument Manufacturing Co., Ltd.

has been suspended since 1957 is resumed, and unit furniture and single-piece foot furniture

are released as the first step.

We received an order for the manufacture of furniture and table legs.

The unit furniture sold much more than originally expected due to the merit of additional installation and excellent functionality.

The unit furniture sold much more than originally expected due to the merit of additional installation and excellent functionality.

1976

Nippon Musical Instrument Manufacturing Co., Ltd. electric grand pianos (CP-70, 80).

We received an order for the CP-70 stand.

We received an order for the CP-70 stand.

1977

Construction of a warehouse at the Terawaki factory

To the next era

A big turning point and a big leap forward

1980

1980

Masakazu Kobayashi as president

1981

Started QC activity “Go-Up Activity”. Create a group for each workplace and engage in activities.

1982

Developed the first production management system by introducing a computer.

1984

Started business with Nippon Columbia Co., Ltd.

1985

In March, Established Entech Co., Ltd. for software development.

In July, Nippon Musical Instrument Manufacturing Co., Ltd. released the Clavinova CVP series. The company has begun production of Clavinova since 1982, and this CVP series became a major driving force for the spread of Clavinova, which was expected as the "third instrument" following piano and Electone.

In November, the Clavinova CLP series was released, and we manufactured the legs of Gravinova.

In July, Nippon Musical Instrument Manufacturing Co., Ltd. released the Clavinova CVP series. The company has begun production of Clavinova since 1982, and this CVP series became a major driving force for the spread of Clavinova, which was expected as the "third instrument" following piano and Electone.

In November, the Clavinova CLP series was released, and we manufactured the legs of Gravinova.

1987

Electone HX released this year.

By adopting the unit method, the world of Electone was further expanded.

1988

Established Ryuzenji Kita Factory and Nanyo Parts Warehouse to expand the assembly process.

In May, a CAD design system was introduced.The design was made more sophisticated and efficient.

In May, a CAD design system was introduced.The design was made more sophisticated and efficient.

1989

Developed die height adjustment machines “DA-100M” and “DA-800M” for press dies.

Established a total production management system by bringing each factory online.

Established a total production management system by bringing each factory online.

1990

Received an order for production of Toshiba dryer parts.

1991

The company color was changed to yellow and the uniform was renewed.

1993

Constructed a new Ryuzenji factory.

A universal precision gear cutter introduced by Kowa Seisakusho at the time of its establishment was displayed at the entrance.

A universal precision gear cutter introduced by Kowa Seisakusho at the time of its establishment was displayed at the entrance.

1994

Die height adjuster for press machine

It was registered in the Patent Register of the Patent Office on June 7.

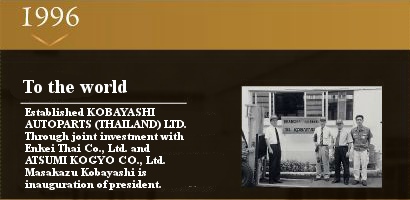

To the world

Look to the world and fly to the world

1996

1996

The second person from the right is President Kobayashi

1997

In April, Started business with Yamaha Corporation's Living Kitchen Division.

Started production of kitchen chairs and dust wagons.

Received an excellence award from Yamaha Corporation.

1998

In July, the shaft processing of the Ryuyo factory was integrated,

and the polishing processing equipment was relocated from the Terawaki factory.

In October, the capital of KOBEYASHI AUTOPARTS (THAILAND) LTD. Was increased to 31,5 million baht.

Received an excellence award from Yamaha Corporation.

In October, the capital of KOBEYASHI AUTOPARTS (THAILAND) LTD. Was increased to 31,5 million baht.

2001

In August, a new plant of KOBEYASHI AUTOPARTS (THAILAND)LTD. Was completed.

(Site area 7.200m2/ Building area 1.500m2)

(Site area 7.200m2/ Building area 1.500m2)

2002

Started business with YAMAHA MOTOR MANUFACTURING CORPORTION OF AMERICA.

2004

In March, established PT.KOBAYASHI AUTOPARTS INDONESIA in Indonesia.

Production will begin in October.

In April, the musical instrument parts division was spun off.

Integrated with Ishii Corporation System Division to establish KIS Co., Ltd.

KOBAYASHI AUTOPARTS (THAILAND)LTD. Factory expanded.(2.266m2)

Production will begin in October.

2005

In April, KOBEYASHI AUTOPARTS (THAILAND)LTD. Was expanded.(The floor area is 4.090m2)

In August, the KIS Co., Ltd. production division was consolidated at the Toyooka factory.

As a result, Kobayashi Industrial Co.,Ltd. has a production base with three production sites: Terawaki Factory, Iwata Factory, and Ryuzenji Factory.

As a result, Kobayashi Industrial Co.,Ltd. has a production base with three production sites: Terawaki Factory, Iwata Factory, and Ryuzenji Factory.

Group

For further challenges

2006

2006

Started corporate development as a group.

2007

In December, the Iwata Factory was expanded.

2013

In September, KOBEYASHI AUTOPARTS (THAILAND)LTD. Second factory completed.

2015

In December, Started operation of solar power generation system at Iwata factory.

2022

In January, Started operation of self-consumption solar power generation system at Terawaki factory.

In April, Nobuhiro Kobayashi appointed President and Representative Director.

Contact us

Contact us +81-(0)53-441-2871

+81-(0)53-441-2871 JAPANESE

JAPANESE HOME

HOME

A small factory built in the post-war burnt fields. Please take a look at the history of Kobayashi-Ind. starting from Kobayashi Seiki Manufactory, which mainly manufactures parts for motorcycles and musical instruments.

A small factory built in the post-war burnt fields. Please take a look at the history of Kobayashi-Ind. starting from Kobayashi Seiki Manufactory, which mainly manufactures parts for motorcycles and musical instruments.

Mold/Jig

Mold/Jig